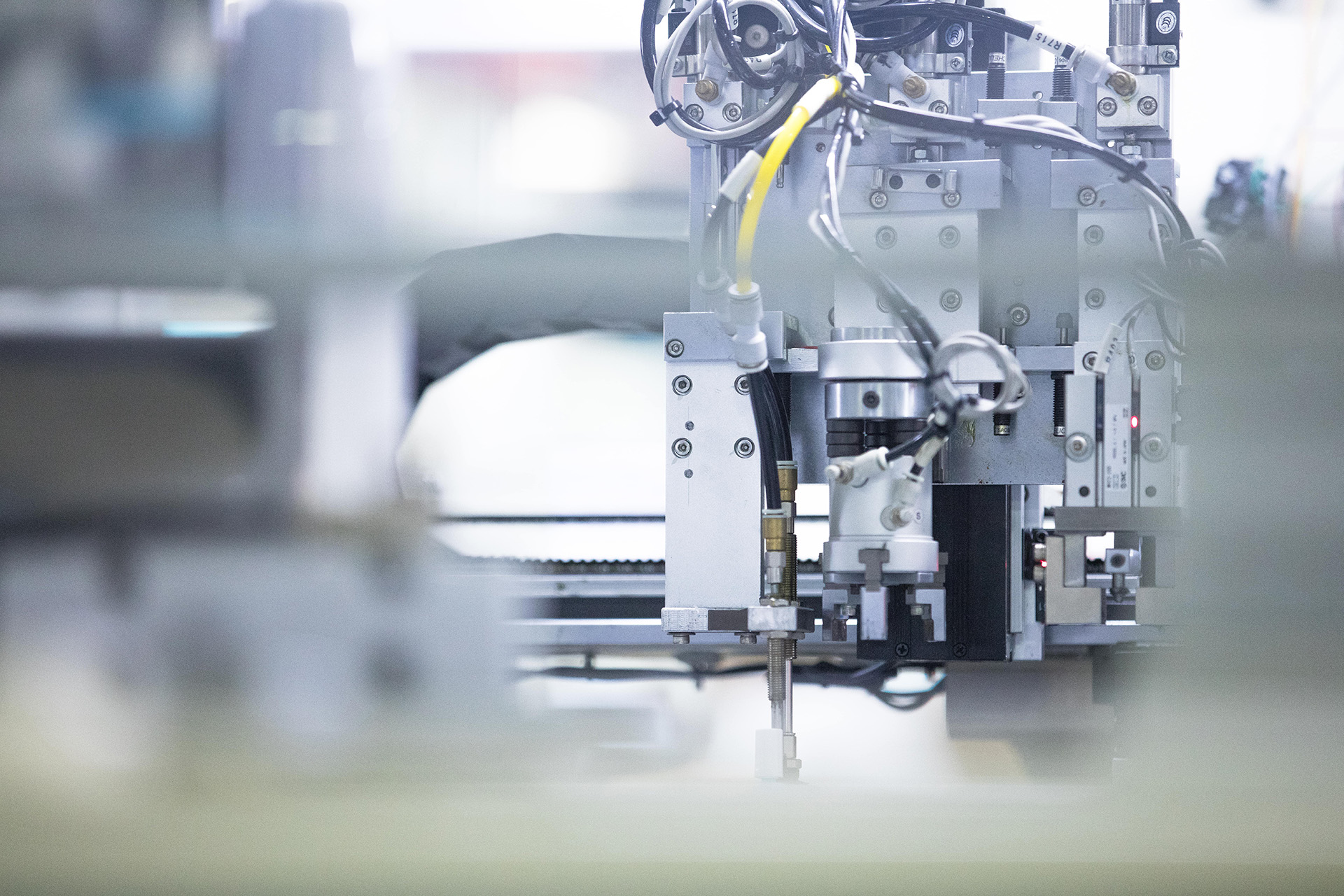

The method of using milling machine processing equipment to process various workpieces. The main processing methods of milling machine processing include turning, drilling, boring, milling, planing, honing, super finishing and polishing. The precision and surface roughness of the milling machine can be processed in a wide range, and higher processing precision and low surface roughness can be obtained. These are the advantages of mechanical processing.

The fastening part of the cutter body tool processed by the milling machine; the face of the rake face facing the direction of the cutting speed; the face opposite to the cutting surface of the main rear face; the face of the secondary rear face opposite to the machined surface; the rake face of the main cutting edge and the main rear face Intersection line; the intersection line between the rake face of the secondary cutting edge and the secondary rear face; the place where the main cutting edge of the nose and the secondary cutting edge intersect; dimensional accuracy refers to the actual value and ideal of the diameter, length, distance between the surfaces of the part The closeness of the value.

With the development of science and technology, milling machine processing is also developing in the direction of high precision, high efficiency, automatic generation, flexibility and intelligence. In the process of developing to metal processing plants, we still need to understand the mechanical processing knowledge. To understand carefully, so as to better meet the challenge. Process system vibration Process system vibration causes the tool to produce periodic displacements on the workpiece, forming traces similar to ripples on the machined surface, so that vibration should be avoided as much as possible during surface rough cutting.